The 2035 Supply Chain Vision

- 25 August, 2025

- Posted by: admin

- Categories: Künstliche Intelligenz, Strategie

From the operational chain to the strategic ecosystem

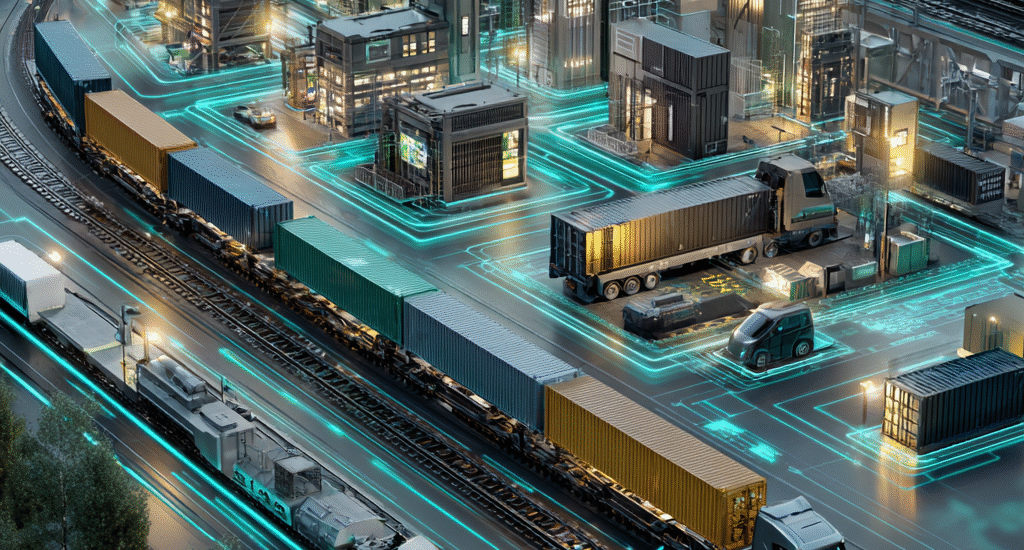

In 2035, the supply chain will no longer be described as a “chain.” The term implies linearity, predictability, and central control—characteristics that will hardly exist in global value networks in the coming decade. Instead, we will see dynamic, self-regulating ecosystems in which decisions are made in milliseconds based on AI-generated scenarios. The most successful companies will not be those that plan best, but those that react fastest and most accurately – without human intervention in operational execution.

This development is not a distant dream. The course for it is being set today, in boardrooms that are still strongly bound to old paradigms. Anyone who wants to be competitive in 2035 must start in 2025 to align governance, technology, and partner networks so that they are prepared for a world in which predictability is only a relative term.

From linear processes to circular decision-making architectures

Historically, supply chains were based on a push-pull mechanism: forecasting, procurement, production, distribution. This linear sequence will be replaced by a circular decision-making architecture over the next ten years. Autonomous systems will continuously process market, risk, and capacity data and constantly adapt their strategies—not in monthly or weekly cycles, but in a state of permanent updating.

Digitale Zwillinge werden nicht länger nur Simulationstools sein, sondern operative Steuerzentralen, die mit Agentic AI gekoppelt sind. Diese Kombination erlaubt es, dass die meisten taktischen Entscheidungen – von der Routenplanung bis zur Allokation knapper Ressourcen – autonom fallen, während das menschliche Führungsteam sich auf langfristige strategische Fragen konzentriert.

Three macro trends that will shape the year 2035

1. Geopolitical fragmentation as a permanent factor

The global economy will continue to divide into trading blocs until 2035. Friendshoring, nearshoring, and dual supply chain strategies will become the norm rather than the exception. Supply chains will be structured in such a way that they can respond to geopolitical shocks at any time without losing operational integrity.

2. Climate variability as a planning parameter

Climate risks are no longer considered an external disruptive factor, but rather an integral part of any capacity planning. Autonomous systems will incorporate real-time weather, harvest, and energy price data into production and distribution decisions.

3. Economic evaluation of supply chains as an asset class

By 2035, investors will not only evaluate products and markets, but also the resilience and adaptability of a supply chain. Stock market valuations will be influenced by supply chain indicators – similar to ESG scores today.

Case study: The self-managing pharmaceutical supply chain

In 2035, a European pharmaceutical manufacturer orchestrates its entire value creation via a globally distributed network of autonomous agents. Production planning in Ireland responds in real time to a surge in demand in Southeast Asia by booking capacity at a US partner factory – without any human intervention. A sudden shortage of raw materials in India is compensated for within seconds by the system activating alternative suppliers, reallocating transport capacity, and automatically initiating contract changes.

The management team not only sees these decisions in reports, but also receives ongoing strategic scenarios: “If we increase production at Plant X by 15%, we will secure market share in Region Y – with a simultaneous margin decline of 2.1%.” This means that boardroom discussions are not based on gut feelings, but on high-resolution projections of the future.

Governance for the Supply Chain 2035

The greatest danger in this transformation is not technological inferiority, but a governance deficit. Autonomous systems require clear ethical guidelines, defined escalation paths, and an understanding of when human intervention is absolutely necessary.

This means:

-

New C-level roles that combine technology, risk, and supply chain.

-

Strategic partnerships with technology providers that enable co-innovation.

-

A data strategy that balances open interfaces and secure collaboration.

Executive Takeaway

The supply chain of 2035 will no longer be a reactive system—it will be a proactive, strategic player. Companies that treat this development as a mere question of efficiency will fail. It is not about “better planning,” but about building a decision-making infrastructure that works in a world of constant uncertainty. The time to start is not 2030. It is now.

SC X AS PARTNER

increase in efficiency

Digitization optimizes business processes and reduces manual effort.

Customer experience

Improved user experience and customer loyalty through intuitive online platforms.

Competitiveness

Use of modern technologies to differentiate ourselves from competitors and tap into new markets.

ability to innovate

Establishment of a framework for continuous innovation and adaptation to changing market conditions.

Business Intelligence

By using advanced data analysis tools and business intelligence solutions, companies can make informed decisions.

Go-to-market partner in Switzerland

We open doors in our network of decision-makers in Switzerland for innovative solution partners from abroad.